Production

We comply with new product manufacturing requirements and relevant laws by promptly introducing advanced technological processes in the production of active pharmaceutical ingredients and finished products. We are increasing production capacities and improving the cost effectiveness of processes in Slovenia and in Krka subsidiaries abroad.

The production in Slovenia is carried out at the locations in Novo mesto, Šentjernej, Krško and Ljutomer; outside Slovenia we have production capabilities in Croatia, Poland, Germany and the Russian Federation.We are also leasing long-term production capabilities for the production of Krka products in China.

We transfer new technologies from development to production; we do the same at Krka’s plants abroad and at the sites of our contractual partners. By providing solutions to technological issues and optimising product production we participate in the development and introduction of new products, new technologies and technological procedures.

The production in Slovenia is carried out at the locations in Novo mesto, Šentjernej, Krško and Ljutomer; outside Slovenia we have production capabilities in Croatia, Poland, Germany and the Russian Federation. We are also leasing long-term production capabilities for the production of Krka products in China.

We transfer new technologies from development to production; we do the same at Krka’s plants abroad and at the sites of our contractual partners. By providing solutions to technological issues and optimising product production we participate in the development and introduction of new products, new technologies and technological procedures.

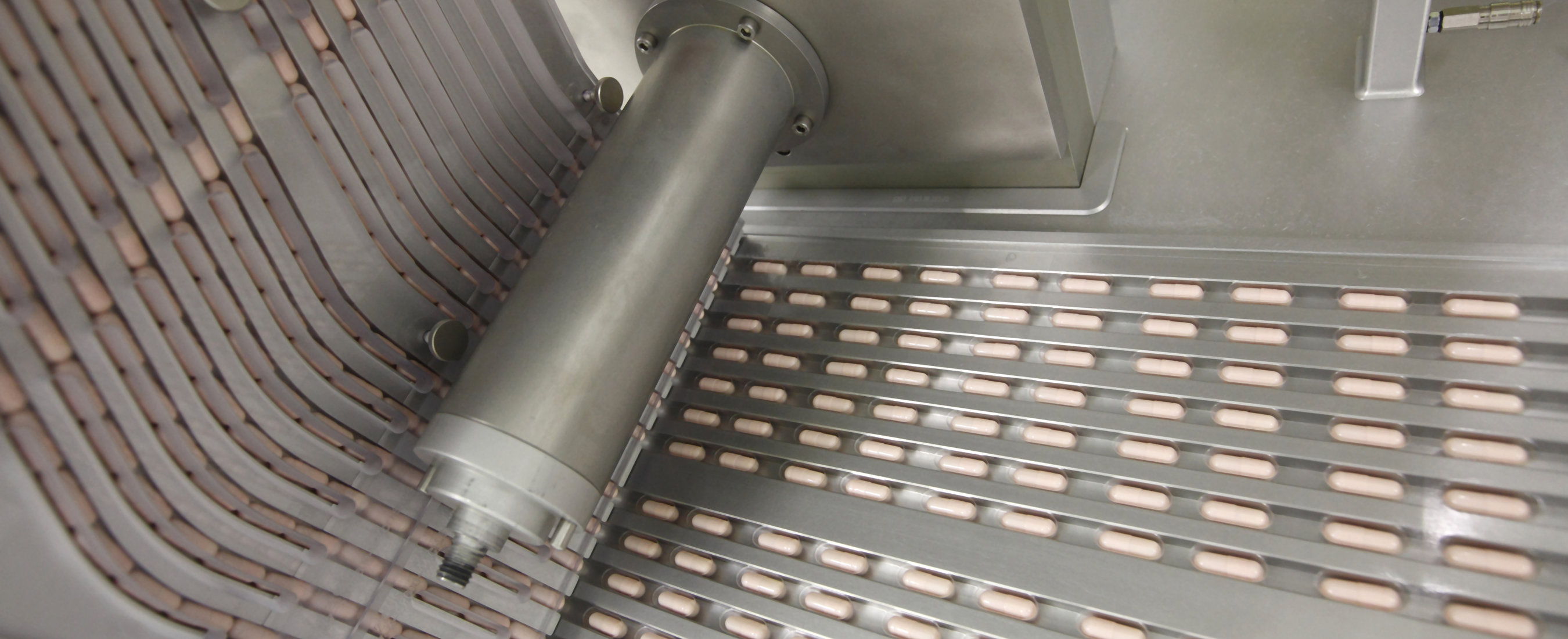

PHARMACEUTICAL PRODUCTION

A pharmaceutical production technologist must have extensive knowledge of the process of producing a wide range of technological forms of medicines, properties of the incoming materials and mechanical equipment, as well as their interactions and interdependencies. Professional knowledge must be regularly shared with others and complemented with new developments in industrial pharmacy, mechanical equipment, regulatory affairs and computer programs that are an indispensable tool for planning, executing and controlling the production process, as well as producing documentation.

The production process is implemented by operators – machine operators, who in turn are guided and monitored by pharmaceutical and chemical technicians. The key to producing high-quality, safe and effective medicines lies in their familiarity with the technological process and the equipment, their extensive work experience and consistency, and the provision of first-class technological documentation. Technologists and maintenance technicians are well versed in mechanical engineering and electronics – they provide technical support and maintain technological equipment.

The production of medicines has the same importance as the cleaning of rooms and equipment. Machine operators clean technological equipment, whereas the production rooms themselves are cleaned and disinfected by qualified cleaning personnel.

API PRODUCTION

An API Production technologist must have extensive knowledge of the entire API production process, technological forms of medicines, properties of materials and mechanical equipment, as well as their interactions and interdependencies.

Professional knowledge must be regularly shared with others and complemented with new developments in industrial pharmacy, mechanical equipment, regulatory affairs and computer programs that are an indispensable tool for planning, executing and controlling the production process and producing documentation.

OUR STATE-OF-THE-ART PRODUCTION FACILITIES IN SLOVENIA AND ABROAD PRODUCE MORE THAN 16 BILLION TABLETS AND CAPSULES EVERY YEAR.

Our high-quality, safe and effective medicines are produced by around 3,000 employees working at nine production facilities in Slovenia, four production companies abroad and at select contractual partners worldwide.